Home Products Rubber Part Rubber Oil Seal TC Skeleton Oil Seal

Description:

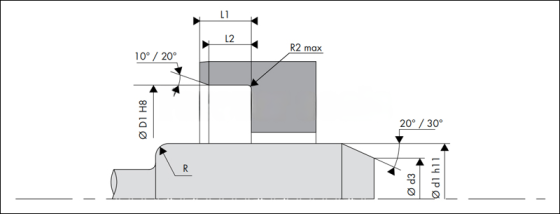

TC

oil seal is a mechanical element used to seal oil, which isolates the parts

that need to be lubricated in the transmission parts from the output parts, so

as not to allow the leakage of lubricating oil. The seals used for static seals

and dynamic seals (generally reciprocating motion) are called seals. The

skeleton oil seal structure consists of three parts: oil seal body, reinforced

skeleton, and self-tightening coil spring. The representative form of the oil

seal is the TC oil seal, which is a double-lip oil seal with a self-tightening

spring completely covered by rubber. Generally speaking, the oil seal often

refers to this TC skeleton oil seal.

TC

oil seal is a mechanical element used to seal oil, which isolates the parts

that need to be lubricated in the transmission parts from the output parts, so

as not to allow the leakage of lubricating oil. The seals used for static seals

and dynamic seals (generally reciprocating motion) are called seals. The

skeleton oil seal structure consists of three parts: oil seal body, reinforced

skeleton, and self-tightening coil spring. The representative form of the oil

seal is the TC oil seal, which is a double-lip oil seal with a self-tightening

spring completely covered by rubber. Generally speaking, the oil seal often

refers to this TC skeleton oil seal.

Application:

Working machinery and equipment, engineering machinery and equipment, means of transportation, conveying equipment, machinery manufacturing, agricultural machinery, etc. Widely used in automobiles, motorcycles, crankshaft, camshaft, differential, shock absorber, engine, axle, front and rear wheels and other parts.

Main Technical Data:

|

Seal Ring Material: |

NBR, FKM, HNBR. etc. |

|

Temperature Range: |

-25°C-100°C,-20°C-250°C. |

|

Medium: |

Mineral oil, Synthetic oil, Grease, Water. |

|

Pressure: |

0-0.03Mpa |

|

Material Hardness: |

70(SHA) |

|

Linear Velocity: |

≤15m/s |

|

Size Range: |

ID 4-1000mm |

Reasonable use of oil seals, should pay

attention to the following points:

(1) the speed of the shaft, due to the design and

structural reasons, high speed shaft should use high-speed oil seal, low speed

shaft using low speed oil seal, can not use low speed oil seal for high-speed

shaft, and vice versa.

(2) when environment temperature is high,

polypropylene, silicon, fluorine and fluorosilicone rubber should be chosen.

And try to lower the oil temperature in the tank. When the temperature is too

low, cold resistant rubber should be used.

(3) the pressure of the oil seal is poor, and the

oil seal will deform when the pressure is too great. Under the condition of

excessive pressure, the pressure bearing ring or the strengthened pressure seal

shall be adopted.

(4) the eccentricity of the installation, when the

oil seal and the shaft are too eccentric, the sealing performance will become

worse, especially when the shaft speed is high. If the eccentricity is too

large, the oil seal with 'W' cross section can be adopted.

(5) the surface smoothness of the shaft directly

affects the service life of the oil seal, that is, the shaft has a high degree

of finish, and the service life of the oil seal will be longer.

(6) pay attention to a certain amount of

lubricating oil in the lip of the oil seal.

(7) special attention should be paid to preventing

dust from being immersed in oil seals.

About OvictorGroup

With

over 23 years of global experience in the sealing industry and Industrial glass

field, OVICTORGROUP is an industrial parts supplier that sources distributes,

and supplies OEM and aftermarket parts for all applications including

construction, aviation, agriculture, marine, and many more. Research and

development of new materials and processes is our passion and our priority is

to provide you with the best possible experience and product.

Our

team can locate any seal for you such as O-Rings, Oil Seals, U-Seals, gaskets,

and Gland Packing. and more. If you need help finding a very specific seal,

reach out to us by phone, email, our live chat support, or even on social

media.

If

it exists, we will find it. if it does not exist, we will customize it.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.