Bonded seals are metal washers with vulcanized rubber sealing lip which are used for sealing function. It was originally designed to replace copper type washers in high-pressure systems. Often used as bolt seals in hydraulic equipment, today bonded seals are finding usage in many and varied applications throughout various industries.

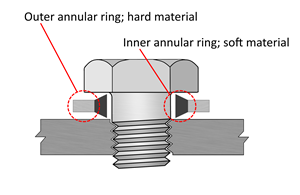

Bonded seals are metal washers with vulcanized rubber sealing lip which are used for sealing function. It was originally designed to replace copper type washers in high-pressure systems. Often used as bolt seals in hydraulic equipment, today bonded seals are finding usage in many and varied applications throughout various industries. A bonded seal is a type of washer used to provide a seal around a screw or bolt. The Bonded Seal comprises a metal washer and an elastomeric ring bonded inside the diameter. A bonded seal consists of an outer annular ring of a hard material, (typically stainless steel SS316, SS304, aluminum, brass, etc) and an inner annular ring of an elastomeric material that acts as a gasket. It is the compression of the elastomeric part between the faces of the parts on either side of the bonded seal that provides the sealing action. The elastomeric material, typically NBR, HNBR, FKM, EPDM, is bonded by heat and pressure to the outer ring, which holds it in place. The metal washer prevents over-compression and limits deformation of the elastomeric ring. This structure increases resistance to bursting, increasing the pressure rating of the seal. Because the bonded seal itself acts to retain the gasket material, there is no need for the parts to be sealed to be shaped to retain the gasket. This results in simplified machining and greater ease of use as compared to some other seals, such as O-rings. Some designs come with an additional flap of rubber on the internal diameter to locate the bonded seal at the center of the hole, these are called self-centring bonded washers.

Advantages

1. Versatile, applicable to all threaded bolts, studs, and clearance holes.

2. Sealing washers are available for metric, Whitworth, and BSP threads.

3. Reliable and suitable for high and low-pressure sealing.

4. Available in different temperature ranges.

5. Easy installation.

6. The rubber and metal combination prevents over-compression and extrusion.

7. cost-efficient solution for bolt/thread sealing.

Type of Bonded Seal

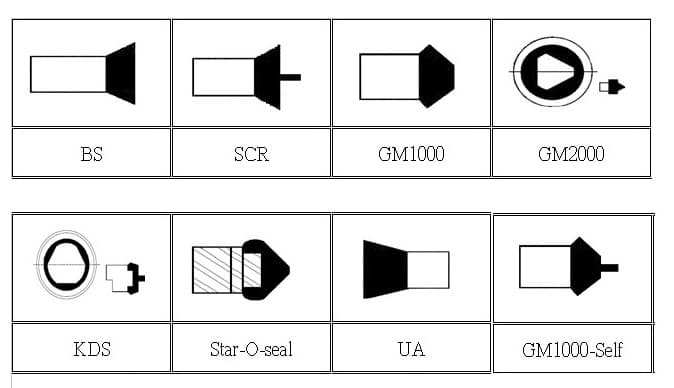

· BS

/ GM500 / U-Seal

-

Can be used to seal clearance or tapped holes in general engineering using a

wide range of different bolts

- Can be used on flat flanges or with recessed bolt holes

· SCR

/ GM500 self-centering

-

Concentrically located

-

Positively retained

-

Ability to pre-assemble

-

Ease of assembly

-

All European thread sizes available

· GM1000 Sealing Ring

- Good sealing function with a low tightening moment - No need of a countersink to center the seal, this is achieved thanks to the design of the sealing lip

-

Mostly used together with metric bolts with hexagonal headsasper DIN

specification

-

On request GM 1000 can also be made for inch threadsaswellasfor special bolt

· GM2000 Sealing Ring

-

Rubber to metal bonded seal with specially designed sealing lip for threads and

nuts

-

No need of a countersink to center the seal, this is achieved thanks to the

design of the sealing lip

-

The seal prevents leakage by sealing in the thread

-

The three contact lips of the rubber body seal the thread to nut and machine

component

-

Positively retained

-

Mostly used together with hexagonal nuts as per DIN specification as well as

for threaded connectors and adjusting screws

· KDS Sealing Ring

-

Rubber and metal bondeding, EO-3 soft sealing ring for Banjo Fitting.

-

EO-3 is an innovative Parker flareless fitting for metric tubing similar to the

EO and EO-2 series.

The

EO3 flareless fitting system utilizes a visual indicator to prevent leakage due

to inadequate

or over-tightening, allowing the user more control to make high-quality, fast connections.

Technical Data

Operating pressure:

Max pressure is dependent of design, material choice and dimensions. Bonded Seals can be designed to withstand from 25 to 200 MPa max pressure.

Please contact us for further information.

Operating temperature:

-30 °C to + 100 °C NBR 70 Shore A

-20 °C to + 100 °C NBR 90 Shore A

-18 °C to + 200 °C FKM 70 Shore A / FKM 75 Shore

-50 °C to + 120 °C EPDM 70 Shore A / EPDM 75 Shore

-10 °C to + 80 °C NBR/PVC blend 60 Shore A

Media:

Mineral oils, water, water-oil emulsion, gases

Bonded seals are available in a choice of materials including:

Rubber Material: NBR, FKM, EPDM, HNBR, SILICONE, NEOP, ACM.

Metal Material: Carbon Steel, SS304, SS316, Aluminum#5052, Copper, AISI#1050.

Surface Treatment: CR3, ZnNi, Phosphate, Anodizing, Cobalt Plating, Tinne Plating.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.