Home Products Rubber Part Large Rubber Parts Rubber Dam System

Along with the development of polymer synthetic materials industry, rubber dam as an innovative hydraulic structure, is composed of high strength fabric as reinforced framework and synthetic rubber which anchored on concrete foundation to form a sealed bag. A layer of stainless steel mesh or ceramic chips can be embedded in the top surface rubber layer to reduce or prevent vandal damage. rubber dam formed by inflating it with water or air through the filling and drainage pipeline. The dam crest can overflow, and the dam height can be adjusted as needed to control the upstream water level. In the dry season, the sealed bag will be filled with water or inflated with air to form a dam for retaining water to meet the water needs of industry, agriculture, and daily use. In the rainy season, discharge the water or air from the sealed bag until the dam falling down which will not influence the flood discharge of the river. With advantages of short construction period, long service life, convenient operation and maintenance, strong seismic resistance, and so on, rubber dams have been widely used in irrigation, power generation, flood control, recreation, and urban environment beautification, etc.

Main Structure

Main Structure

· Civil construction part

· Dam bag

· Anchoring parts

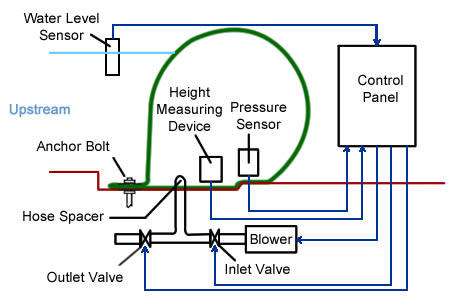

· Filling and draining (air) facilities

· Control system

Classification

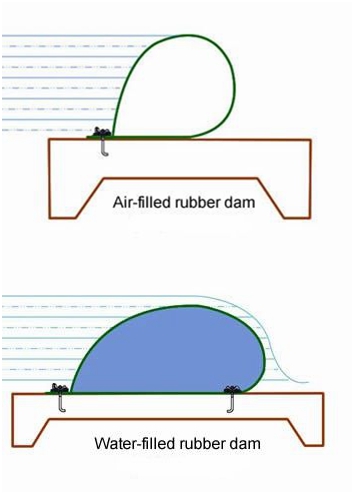

According to the filled medium, it can be classified into water filled rubber dam and air inflated rubber dam.

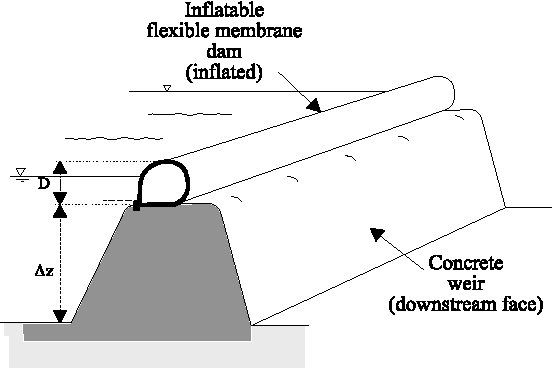

According to the installation form, it can be classified into pillow-like rubber dam and slope rubber dam.

According to anchor form, it can be classified into bolt anchoring and wedge block anchoring.

Advantages

1. Low cost and low consumption.

It can reduce investment by 30% to 70%, and greatly save the consumption of three materials, including: saving steel by 30% to 50%, cement by about 50%, and wood by more than 60%.

2. Low operating and maintenance costs.

Moving parts require no lubrication and no painting. Works well in cold conditions without de-icing and will not seize mechanical parts.

3. The installation is fast and simple, and the construction period is short.

The installation of the dam bag only takes 5 to 15 days, the cycle is short, and the benefits are quick after completion.

4. Anti-seismic, anti-foundation settlement, impact-resistant

The dam body is made of flexible material, which is anti-seismic, impact-resistant and wave-resistant. Strong resistance to foundation deformation and good water-stopping effect. Can accommodate potential uneven settlement of the foundation

5. Simple structure

The single dam has a large span and does not require too many middle piers and other structures. It does not block water during the flood season, has sufficient collapse, and is safe for flood discharge.

6. Security

The rubber dam adopts the latest technology, which is integrally formed and vulcanized at one time. It has the outstanding advantages of consistent and stable overall performance and no safety hazards in splicing. Long-term operation without deformation; and the designed service life of the whole dam bag is 10-15 years longer than that of the rubber dam.

7. Appearance

The color and shape are beautiful, and it is used in the construction of river landscape, which is beneficial to create waterscape and beautify the environment.

Application

· Retain water.

· Adjust the water level.

· Irrigation.

· Generate hydro-electric power.

· Control flood.

· Tidal barriers.

· Control water.

· Shipping.

· Increase reservoir capacity.

· Industrial and agricultural production.

· sewage treatment system

· Ecological protection.

· Develop water entertainment and tourism.

· Urban environment beautification.

Comparison and Choose

1) Rubber dams have many uses. We can check the comparison below and choose Air Filling Rubber Dam or Water Filled Rubber Dam according to different uses and specific conditions.

|

Item |

Water Filled Rubber Dam |

Air Filling Rubber Dam |

|

Outside air temperature |

The internal water of rubber bladder would be frozen in cold temperature |

The internal pressure would change when temperature changes greatly |

|

In hot Area |

The internal water could reduce the outer surface temperature of rubber bladder and prolong the rubber dam service life |

The internal pressure would be very high |

|

Circumference length of rubber bladder |

longer |

shorter |

|

Loading concrete foundation |

Longer with high cost |

Shorter with lower cost |

|

Max. Overflow height |

50% of dam height |

30% of dam height |

|

Stability of rubber bladder during operation |

Stable |

Would vibrate. The vibrasion will be reduced if there is deflector design |

|

Inflation and deflation time |

Longer time |

Shorter time |

|

Inflation and deflation pipe |

Pipe diameter is bigger |

Pipe diameter is smaller |

|

Application in hydraulic power station |

Could adjust the upriver level according to adjust dam height |

Could not adjust upriver water level |

|

Build in spillway of hydraulic power station |

Could not if the spillway is not horizontal |

Could |

2) Air inflated rubber dam data (Air); Water inflated rubber dam data(Water).

|

Height(m) |

Pressure Rate(in/out) |

Radial Strength(kN/m) |

Thickness |

Safety Factor |

|||||

|

Air |

Water |

Air |

Water |

Air |

Water |

Air |

Water |

Air |

Water |

|

1.0 |

1.0 |

1.0 |

1.50 |

5.00 |

5.00 |

10 |

5.5 |

45.00 |

25.60 |

|

1.5 |

1.5 |

1.0 |

1.50 |

11.25 |

11.25 |

10 |

6.2 |

20.00 |

17.78 |

|

2.0 |

2.0 |

1.0 |

1.40 |

20.00 |

18.00 |

10 |

6.8 |

13.50 |

13.33 |

|

2.5 |

2.5 |

1.0 |

1.40 |

31.25 |

28.13 |

10 |

7.3 |

11.52 |

11.38 |

|

3.0 |

3.0 |

0.9 |

1.30 |

40.50 |

36.00 |

12 |

7.9 |

11.11 |

12.22 |

|

3.5 |

3.5 |

0.8 |

1.30 |

49.00 |

49.00 |

12 |

8.5 |

10.10 |

11.43 |

|

- |

4.0 |

- |

1.25 |

- |

60.00 |

- |

10.2 |

- |

12.00 |

|

- |

4.5 |

- |

1.25 |

- |

75.94 |

- |

11.1 |

- |

11.06 |

|

- |

5.0 |

- |

1.20 |

- |

87.50 |

- |

12.7 |

- |

11.65 |

Physical and Mechanical Properties Data

Item

Outer

Middle layer,

Cover rubber

Tensile strength at break

MPa

14

12

6

Elongation at break

%

400

400

250

Permanent deformation at break

%

30

30

35

Hardness (shore A)

55-65

50-60

55-65

Brittleness temperature

°C

-30

-30

-30

Hot water aging

Tensile strength at break

MPa

12

10

5

Elongation at break

%

300

300

200

Hot water aging

Tensile strength at break

MPa

12

10

5

Elongation at break

%

300

300

200

Volume expansion ratio

%

15

15

15

Wear loss (akron)

cm3/1.61 km

1

1

1.2

Ozone aging: 10000 pphm, temperature

40 °C, stretching 20%, no cracking

min

120

120

100

Flexibility, no cracking

Ten thousand

20

20

20

layer

inner layer

sheet

(100 °C × 96 h)

(70 °C × 96 h)

times

Installation

· Mark

dam axes and centerline on pre-concreted foundations.

· Install

embedded anchor bolts and plates.

· Install

nozzle and pipes before concreting.

· Pour

the concrete.

· Cut

and punch holes on rubber bladders for anchor bolts.

· Anchor

rubber bladder and clamping plates. For inclined rubber dam, install the

inflated rubber dam from lower reaches to upper reaches and land wall. As to

pillow-like dam, start from stop-ends at the corner of the dam, and then fasten

the upper and lower reached of the rubber body.

· Retorque

the anchor bolts and seal the bladder.

· Complete commissioning test.

Service Support

1)Whole

Technological Design

We

determine reasonable plans and selections by conducting more systematic

laboratory tests, semi-industrialization tests and theoretical analysis

calculations and adopting appropriate methods in light of the actual problems

faced by customers. And it determines specific parameters through laboratory

tests and semi-industrial tests.

2)Project

Construction

We can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.