Home Products Rubber Part Large Rubber Parts Rubber Water Stop

Description

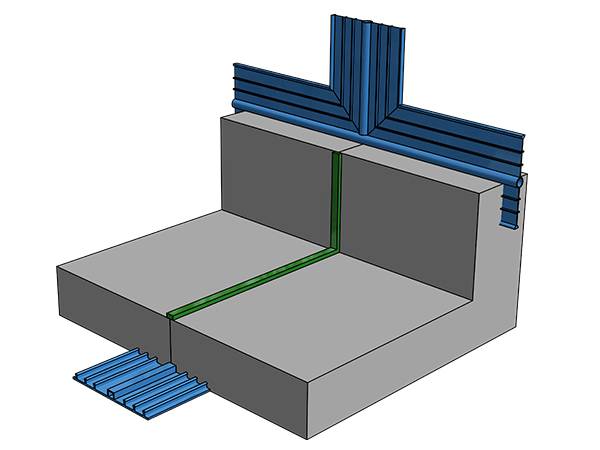

Rubber Water stop has been used extensively on projects throughout t the world. is one of the widest types for concrete structure. Rubber water stops provide superior performance in withstanding shear movements and to resist hydrostatic pressure. Generally, designed to be cast in the concrete as an integral joint sealing system to prevent liquid leaking in or out. made of quality SBR (styrene butadiene rubber), neoprene rubber or natural rubber, rubber water stops are ideal for applications where high physical properties of rubber are required. For example, reservoirs, dams and other water retaining or excluding applications with high movements or water pressure.

Rubber Water stop has been used extensively on projects throughout t the world. is one of the widest types for concrete structure. Rubber water stops provide superior performance in withstanding shear movements and to resist hydrostatic pressure. Generally, designed to be cast in the concrete as an integral joint sealing system to prevent liquid leaking in or out. made of quality SBR (styrene butadiene rubber), neoprene rubber or natural rubber, rubber water stops are ideal for applications where high physical properties of rubber are required. For example, reservoirs, dams and other water retaining or excluding applications with high movements or water pressure.

Applications

· Water and sewage disposal projects.

· Liquid containments.

· Dams, channels, tunnels and tanks.

· Box culverts and locks.

· Primary and secondary containments structures.

· Bridges and decks abutments.

· Wall and slabs.

· Basements and foundations

· Chemical areas.

Feature

· Good waterproof performance.

· High tensile strength, and good elasticity.

· Can withstand a certain degree of bending and pressure.

· Rust, wear, aging, tear, corrosion resistance.

· Adapt the deformation of concrete.

· Can arise compression deformation under various loads.

· Capable to withstand hydrostatic pressure.

· Temperature range from -45°C to +60°C.

· Non-toxic, not pollute the environment.

· Unequal thickness structure can ensure each part of the sections can get uniform and reasonable force.

· Setting holes ensure the water stop fix with the nearest steel bar convenient and firmly.

· Easy to install.

· Long service life.

Classification

The selection of the right water stop depends on the type of structure, level of exposure and construction method. Water stops are available in different shapes and materials. Different types of water stops are should used in different parts of the project.

1) According to the model, it can be classified into: embedded rubber water stop with holes in the middle; embedded rubber water stop with no holes in the middle; externally attached rubber water stop with holes in the middle;

2) According to the material, it can be classified into natural rubber water stop, neoprene water stop, and EPDM rubber water stop.

3) According to the usage, it can be classified into: buried rubber water stop and back-mounted rubber water stop (outer-mounted rubber water stop), steel-edged rubber water stop, water-swellable rubber water stop, and flat rubber water stop Waterstops, water stops for deformation joints, water stops for construction joints, and water stops for joints with special anti-aging requirements.

Technical Data

|

Items |

Parameter |

||

|

Hardness (Shore A) |

60 ± 5 |

||

|

Tensile strength (MPa) |

≥ 8 |

||

|

Elongation at break (%) |

≥ 380 |

||

|

Compression set |

70 °C 24 h (%) |

≤ 35 |

|

|

23 °C 168 h (%) |

≤ 20 |

||

|

Brittleness temperature (°C) |

≤ -45 |

||

|

Hot-air aging 70 °C × 72 h |

Hardness (Shore A) |

≤ +8 |

|

|

Tensile strength (N/mm²) |

≥ 10 |

||

|

Elongation change rate (%) |

≤ 20 |

||

Installation

1) Before installation, uncoil waterstops (especially for those waterstops have shape-memories) to let it resume straight shape - that makes waterstop easy to handle and fabricate.

2) Check the waterstop whether it has any defects or cracks. Replace the defective and unacceptable waterstops.

3) Place waterstops at appropriate position. Make sure that about a half width of it is embedded in the concrete.

4) Contain about 1.5 times of clear coverage between the waterstop and surround reinforcing steel without any rock pockets and air voids.

5) Tie the waterstop to surrounding reinforcing steels by threading steel wire to metal eyelets, punched holes or hot rings of waterstops to fix the waterstop firmly. Meanwhile, make sure there is no displacement during fastening.

6) Pour the concrete and vibrate concrete nearby the joints (especially those under the waterstop) to enhance the contact with waterstops.

7) Clean debris and dirt of concrete surface after first pour.

8) Repeat the above methods for a second pour.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.