Home Products Rubber Part Rubber Seal Ring Rubber O-Ring Seal

Description and Working Principle:

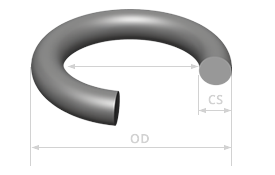

Rubber O-ring

is an essential sealing element in industrial equipment. It is made of elastic

polymer material and has good sealing performance and wear resistance. It can

be used for both static and dynamic seals. It is generally installed in a

groove with a rectangular cross-section on the inner circle or outer circle to

act as a seal. As a widely used seal, it has many advantages such as convenient

manufacture, reliable function, simple installation, and low price. It has

waterproof, gas-proof, oil-proof, leak-proof, and other sealing functions. The

working pressure range is 0-30MPa, the working speed is less than or equal to

15m/s, the working temperature range is -55~250℃, and the hardness

standard range is 70~90 degrees. It is suitable for hydraulic oil, gas, water,

acid, crude oil, mud, emulsification Liquid, water-ethylene glycol, and other

media.

Rubber O-ring

is an essential sealing element in industrial equipment. It is made of elastic

polymer material and has good sealing performance and wear resistance. It can

be used for both static and dynamic seals. It is generally installed in a

groove with a rectangular cross-section on the inner circle or outer circle to

act as a seal. As a widely used seal, it has many advantages such as convenient

manufacture, reliable function, simple installation, and low price. It has

waterproof, gas-proof, oil-proof, leak-proof, and other sealing functions. The

working pressure range is 0-30MPa, the working speed is less than or equal to

15m/s, the working temperature range is -55~250℃, and the hardness

standard range is 70~90 degrees. It is suitable for hydraulic oil, gas, water,

acid, crude oil, mud, emulsification Liquid, water-ethylene glycol, and other

media.

The rubber O-ring is an extrusion type seal. The basic working principle of the extrusion type seal is to rely on the elastic deformation of the seal to cause contact pressure on the sealing contact surface. If the contact pressure is greater than the internal pressure of the sealed medium, it will not occur leakage, otherwise, leakage occurs.

Classification:

According

to the material, it can be divided into silicone O-ring, nitrile rubber O-ring,

fluororubber O-ring, pu polyurethane O-ring, PTFE O-ring, fluorine rubber

O-ring, etc.

According

to the application, it can be divided into: O-ring for fixed seal, O-ring for

reciprocating motion seal, O-ring for rotary motion seal.

According

to the nature of use, it can be divided into: high-temperature resistant

sealing ring, high-pressure resistant sealing ring, corrosion-resistant sealing

ring, wear-resistant sealing ring.

According to the sealing method, it can be divided into: radial seal, axial seal.

Features:

1)

The structure of the sealing groove is simple, the volume is small, and the

installation position is compact.

2)

It can be sealed in both directions and can be used for dynamic and static

sealing.

3)

It has a self-sealing effect and does not require periodic adjustment.

4)

The dynamic friction resistance is small, and it can also be used in the

occasion of alternating pressure.

5)

Strong adaptability and light use.

6)

The price is low.

7) Excellent elasticity and sealing, good corrosion resistance.

Different Material

Properties and Scope of Use:

1)Nitrile Butadiene Rubber(NBR)

· Advantages: good oil resistance and high temperature resistance. Good abrasion resistance. Solvent resistance and elongation.

· Disadvantages: Not suitable for polar solvents, such as ketones, ozone, nitro hydrocarbons.

· Medium: mineral oil, gasoline, benzene, water.

· Hardness(Shore A): 30-95

· Pressure Range(MP): <32MP

· Temperature Range(℃): -30~120

2)Chloroprene Rubber(CR)

· Advantages: excellent mechanical strength, resistance to buckling fatigue, resistance to animal and vegetable oils, flame retardant properties, etc.

· Disadvantages: Strong acids, nitro hydrocarbons, esters, chloroform and ketones are not available

· Medium: air, water, oxygen

· Hardness(Shore A): 40-90

· Temperature Range(℃): -40~120

3)Butyl Rubber(IIR)

· Advantages: It is impermeable to most gases, has excellent resistance to sunlight and ozone, and has shock absorption and electrical insulation

· Disadvantages: It is not recommended to use with petroleum spirit, kerosene and aromatic hydrogen.

· Medium: Animal and vegetable oils, weak acids, alkalis

· Hardness(Shore A): 65-75

· Temperature Range(℃): -30~110

4)Styrene-Butadiene Rubber(SBR)

· Advantages: excellent wear resistance, outstanding water resistance, good processability and balance of physical properties

· Disadvantages: It cannot be used in strong acids, ozone, oils, greases and fats, and most hydrocarbons.

· Medium: Alkali, animal and vegetable oils, air, water

· Hardness(Shore A): 45

· Temperature Range(℃): -30~100

5)Natural Rubber(NR)

· Advantages: excellent resilience, insulation and water resistance.

· Disadvantages: easy to age in the air, become sticky when heated, easy to swell and dissolve in mineral oil or gasoline, alkali resistant but not strong acid resistant.

· Medium: water, weak acid, weak base.

· Hardness(Shore A): 65-75

· Temperature Range(℃): -30~90

6)Vinyl Methyl Silicone(VMQ)

· Advantages: heat resistance, cold resistance, excellent lubricating oil resistance, water resistance.

· Disadvantages: Cannot be used for most concentrated solvents, oils, concentrated acids and hydrocarbon fuels, aromatic hydrocarbons

· Medium: Mineral oil, animal and vegetable oil, oxygen, weak acid, weak base

· Hardness(Shore A): 30-90

· Pressure Range(MP): <32MP

· Temperature Range(℃): -60~260

7)Polyurethane Rubber(UR)

· Advantages: high hardness, high elasticity, high mechanical strength and good wear resistance, aging resistance, ozone resistance.

· Disadvantages: Not resistant to high temperature.

· Medium: water, oil

· Hardness(Shore A): 60-94

· Temperature Range(℃): -30~80

8)Fluororubber(FKM)

· Advantages: Excellent heat resistance, oil resistance and fuel oil resistance among synthetic rubber materials

· Disadvantages: poor cold resistance, not suitable for low molecular amine, ammonia, hydrofluoric acid, chlorosulfonic acid, phosphoric acid, ketone, ether, ester hydraulic oil

· Medium: All lubricating oils, steam, air, inorganic acids, halogen solvents, etc.

· Hardness(Shore A): 60-90

· Pressure Range(MP): <32MP

· Temperature Range(℃): -20~200

9)Perfluoroelastomers(FFKM)

· Advantages: Excellent high temperature resistance, aging resistance, vacuum resistance, mechanical resistance

· Disadvantages: Expensive

· Hardness(Shore A): 65-75

· Temperature Range(℃): -45~320

10)Acrylic Rubber(ACM)

· Advantages: good resistance to petrochemical oil, high temperature resistance, weather resistance and resistance to mineral oil

· Disadvantages: Weaker in terms of mechanical strength, shrinkage deformation rate and water resistance

· Hardness(Shore A): 70

· Temperature Range(℃): -20~180

11)Ethylene Propylene Diene Monomer(EPDM)

· Advantages: Excellent resistance to active oxygen, ultraviolet light, weather resistance and aging resistance. Electrical insulation performance, chemical resistance, impact ductility are very good, corrosion resistance, polar solvent resistance ketone, ester, etc., high temperature steam resistance, excellent impermeability to gas.

· Disadvantages: not resistant to hydrocarbon derivatives and aliphatic hydrocarbons.

· Hardness(Shore A): 65-75

· Temperature Range(℃): -50~+150

12)Hydrogenated Nitrile Rubber(HNBR)

· Advantages: high impact toughness and wear resistance, heat resistance, ozone resistance, chemical resistance and mechanical properties

· Disadvantages: Can not be used in alcohols, esters or aromatic solutions

· Hardness(Shore A): 50-90

· Temperature Range(℃): -25 ~ +150

13)Fluorosilicone Elastomer(FVMQ)

· Advantages: good oil resistance, solvent resistance, heat resistance, cold resistance, high voltage resistance, weather aging resistance and other excellent properties

· Disadvantages: not suitable for low molecular amine, ammonia, hydrofluoric acid, chlorosulfonic acid, phosphoric acid, ketone, ether, ester hydraulic oil

· Medium: Aliphatic hydrocarbons, aromatic hydrocarbons, chlorinated hydrocarbons, various petroleum-based fuel oils, lubricating oils, hydraulic oils, and certain synthetic oils

· Hardness(Shore A): 70-80

· Pressure Range(MP): <32MP

· Temperature Range(℃): -60~+170

14)Polytetrafluoroethylene(PTFE)

· Advantages: low temperature resistance, high temperature resistance, corrosion resistance, weather resistance, high lubrication, non-adhesion

· Disadvantages: cold flow, non-viscous, large and irregular expansion coefficient

· Medium: Acids, alkalis, various solvents

· Temperature Range(℃): -100~260

How to choose rubber O-ring?

When

choosing an O-ring, compatibility with the working medium must first be

considered. Secondly, the working conditions such as pressure, temperature,

continuous working time, and operating cycle of the seal are considered

comprehensively. The correct selection of rubber O-rings needs to consider the

following key indicators.

1)

Environment:

· Objects to

be in contact with, including liquids, gases, solids and various chemicals.

· Temperature

range, minimum and maximum temperature.

· In the

pressure range, when the seal is under pressure, the minimum reduction ratio

should be considered.

· Consider

the type of dead load, static or dynamic.

2)

Structure:

· Consider

combinations.

· Consider

chemical changes that may occur during use.

· Take into

account the service life and possible causes of failure.

· Consider

the degree of lubrication of the parts and the method of assembly.

· Consider tolerance angles.

3)

Parameters:

· Size.

· Hardness.

· Extrusion

gap.

· Compression

set.

· Pre-compression.

· Stretch

and squeeze.

· Color.

Installation Precautions:

· Clean the installation location and remove all processing residues.

· Chamfer or blunt the edges or transition holes and remove burrs.

· Apply lubricant to the rubber O-ring.

· Make sure that the sealing surface is not damaged.

· Confirm again whether the size of the rubber O-ring is correct.

· Use corresponding installation tools to install the seals that need to be

deformed.

· The thread on the installation path needs to be provided with a protective

sleeve to prevent the sharp corner of the thread from scratching the O-ring.

· When installing manually, do not use sharp tools, and use tools as effectively as possible to ensure that the O-ring is not twisted.

Applications:

Machine tools, ships, automobiles, aerospace equipment, medical treatment, sensors, valves, sanitary ware, toys, bearings, pumps, electronics, electrical appliances, metallurgical machinery, engineering machinery, chemical machinery, construction machinery, agricultural machinery, petroleum machinery, mining machinery, plastics Machinery and various instruments and meters, etc.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.