Home Products Rubber Part Rubber Seal Ring Rubber V-Ring Seal

Description:

V-rings

are unique all-rubber seals for rotating shafts. It is a lip seal. V-rings are

excellent seals against the ingress of dirt, dust, water, or a combination of

these media while retaining absolute grease. Due to its unique design and

performance, the V-ring can be used in a wide range of various types of

bearings, and it can also be used as a secondary seal to protect the main seal.

V-rings

are unique all-rubber seals for rotating shafts. It is a lip seal. V-rings are

excellent seals against the ingress of dirt, dust, water, or a combination of

these media while retaining absolute grease. Due to its unique design and

performance, the V-ring can be used in a wide range of various types of

bearings, and it can also be used as a secondary seal to protect the main seal.

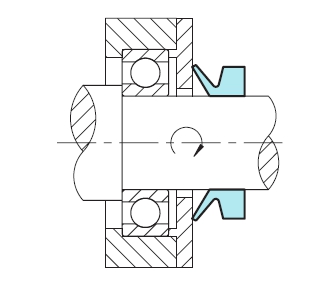

The V-shaped sealing ring device is composed of three parts: a support ring, a sealing ring, and a pressure ring. The standard included angle of the V-shaped sealing ring is 90°, and 60° is also used on special occasions. The support ring is an important part to support the V-shaped sealing ring. Its section is thick and strong, with precise dimensions, and the concave angle is the same (90°) or slightly larger than that of the V-shaped sealing ring so that the sealing ring can be placed stably. The function of the compression ring is to create an initial compression amount for the V-shaped sealing ring so that it can fully contact the sealed surface, and the compression amount of the V-shaped sealing ring can be adjusted. V-ring seals are usually stretched and mounted directly on the shaft, holding them in place by the inherent tension of the rubber body. It rotates with the shaft and seals axially on a stationary mating surface perpendicular to the shaft. The mating surface can be the sidewall of a bearing or washer, a stamping, a housing, or even the metal housing of an oil seal. The sealing lip is flexible and exerts only relatively little contact pressure on the mating surface, but still enough to maintain the sealing function. Low contact pressure (varies with installation width) allows the seal to run dry in many applications.

Advantages:

1.

Low friction and therefore lower power losses related to the application of oil

seals.

2.

Long lifetime.

3.

Simple construction; no seal housing is required.

4.

The shafts do not need a special surface treatment.

5.

Simple mounting.

6.

No wear of the shaft.

7. Dual function: as a seal and as a flinger through which possible dirt and liquids are thrown away.

8.

The flexible lip is unlikely to become damaged during storage and assembly.

9. applicable for a wide range of shaft diameters. With 85 sizes shaft sizes from 3 till 2000 mm (1/8" to 80").

10.

Suitable for high RPM.

11.

Misalignment of the shaft has no negative effect on the functioning of the V-ring.

12. Attractive pricing.

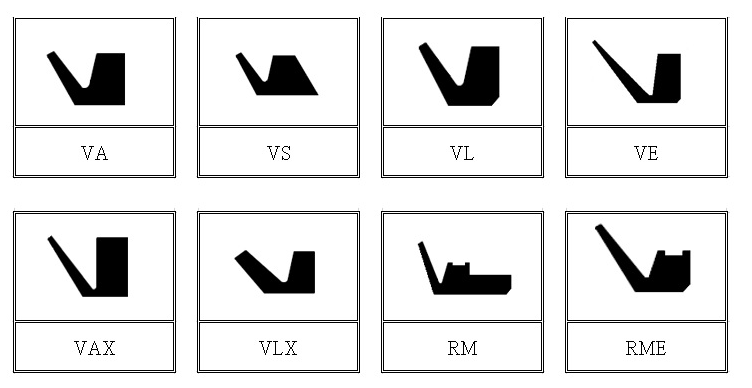

Type of V-Ring:

· The VA

is the most common and fits diameters from 2.7 to 2020 mm (inclusive).

· The

VS is wider and tapered for a very firm fixation on the shaft. This ring is

suitable for diameters from 4.5 to 210 mm.

· The

section of VA and VS increases with the diameter of the shaft, while the

section of other types is the same in the whole diameter range.

· The VL

and VLX have narrower axial sections, they are suitable for compact spaces and

are often used in combination with labyrinth seals, suitable for diameters from

105 (135 for LX) to 2025mm.

· The RME, RM and VAX are heavy duty V-rings originally designed for large high speed bearing arrangements i.e. rolling mill and paper machine applications. In addition, they can also be used as a secondary seal for heavy-duty applications to protect the primary seal from the ingress of water and particulate contamination.

· The RME, RM and AX types use specially designed clamping collars that can be set axially and radially on the shaft, suitable for shaft diameters from 300 mm and above.

Material:

The material of the V-ring is commonly used in nitrile rubber and neoprene, natural rubber is used for sealing water and air, butyl rubber is used for non-flammable hydraulic oil, and phosphate ester hydraulic oil. Chlorine rubber is used in various chemicals and high temperatures. When wear resistance is required, polyurethane rubber is used. Fabric rubber is also a common material for V-rings. Its feature is to increase the rigidity and strength of the sealing ring to prevent rubber extrusion and gap bites, making it suitable for high pressure. At the same time, during the wear process, the rubber wears before the fabric, and when the part with high contact pressure expands, the wear of the entire sealing surface tends to be uniform, while the friction does not change significantly. However, the lip of the fabric rubber sealing ring is easy to scrape off the oil film on the sliding surface, so the lubricity is relatively poor. The pressure ring and the support ring are generally pressed with a harder adhesive tape, and the support ring is sometimes pressed with hard plastic.

Installation:

Clean

V-rings, mating surfaces and shaft

Make

sure the shaft is dry and free from grease or oil, especially when installing

V-rings without axial support.

Lubricate

the lip of the V-ring with a thin layer of grease or silicone oil.

In

applications where friction must be kept to a minimum, the mating surfaces

should be coated with a low friction compound. Do not apply oil to lips.

Check that the installed V-ring stretches evenly around the shaft.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.