Description

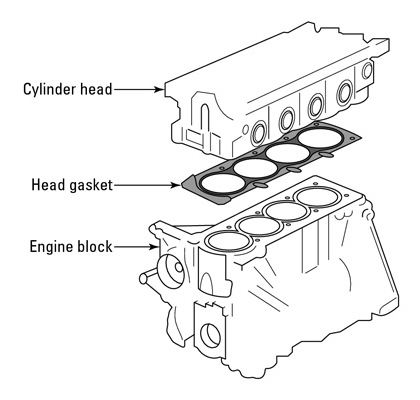

Conventional gasoline and diesel engines are made of two major parts: the engine block, and cylinder head. In order to seal them together, a cylinder head gasket (often called just the “head gasket”) is installed between them. It is an important part of tuning. Its function is to fill the microscopic pores between the cylinder block and the cylinder head to ensure good sealing at the joint surface, thereby ensuring the sealing of the combustion chamber and preventing air leakage from the cylinder and water jacket leakage. A head gasket only works as long as the compression seal is intact – the fact that nothing can get past the seal ensures that the engine works perfectly. This is why a leak in that seal can be so devastating for the car’s performance in both the short and long term. So the importance of cylinder head gasket is self-evident. But unlike any other gasket in an engine, the head gasket has to seal oil, coolant, and compression from the cylinders simultaneously. This makes it the most stressed gasket in an engine, and therefore one of the most likely to fail.

Conventional gasoline and diesel engines are made of two major parts: the engine block, and cylinder head. In order to seal them together, a cylinder head gasket (often called just the “head gasket”) is installed between them. It is an important part of tuning. Its function is to fill the microscopic pores between the cylinder block and the cylinder head to ensure good sealing at the joint surface, thereby ensuring the sealing of the combustion chamber and preventing air leakage from the cylinder and water jacket leakage. A head gasket only works as long as the compression seal is intact – the fact that nothing can get past the seal ensures that the engine works perfectly. This is why a leak in that seal can be so devastating for the car’s performance in both the short and long term. So the importance of cylinder head gasket is self-evident. But unlike any other gasket in an engine, the head gasket has to seal oil, coolant, and compression from the cylinders simultaneously. This makes it the most stressed gasket in an engine, and therefore one of the most likely to fail.

Classification

According to the different materials used, the cylinder head gasket can be divided into metal-asbestos gasket, metal-composite material gasket and all-metal gasket. Both the metal-composite liner and the all-metal liner are asbestos-free cylinder liners, because there is no asbestos interlayer, which can eliminate the generation of air bags in the liner and reduce industrial pollution, which is the current development direction.

1) Metal-asbestos gasket

The metal-asbestos gasket is made of asbestos, covered with copper skin or steel skin, and the other metal-asbestos gasket is made of perforated steel plate as the skeleton, covered with asbestos and binder. All metal-asbestos gaskets All are surrounded by sheet metal around the cylinder bore, coolant hole and oil hole. In order to prevent high-temperature gas ablation liner, a metal frame reinforcement ring can also be built into the metal edging. The metal-asbestos gasket has good elasticity and heat resistance, and can be reused many times. If the asbestos board is impregnated in a heat-resistant adhesive, the strength of the cylinder head gasket can be increased.

2) Metal-composite liner

The metal composite liner is a new type of composite material that is heat-resistant, pressure-resistant and corrosion-resistant on both sides of the steel plate, and is wrapped with stainless steel around the cylinder hole, coolant hole and oil hole.

3) Metal backing

The metal liner has high strength and strong corrosion resistance, and is mostly used in engines with a high degree of strengthening. Commonly used are high-quality aluminum plate cylinder liners, and the coolant holes are sealed with rubber rings. The other is the structure of the stainless steel laminated cylinder liner, and the coolant hole is also sealed with a rubber ring.

What are the symptoms of a failing head gasket?

A failed head gasket must be replaced - a job that could can be cumbersome and time-consuming. so, before you get it replaced by a mechanic, it’s important to figure out why the head gasket failed. otherwise, the replacement gasket is likely to fail as well. There are several symptoms that can indicate a faulty head gasket, including:

· White or blue smoke coming from the exhaust.

· Overheating

· Coolant leaks

· Oil leaks

· Loss of power

How do I install a cylinder head gasket?

After

ordering your parts, we are also happy to give you tips around installation.

Below you will find a step-by-step plan, drawn up by our specialists together

with information. This step-by-step plan is very important to follow for a

correct installation. In addition, our specialists provide tips to make the

installation as smooth as possible.

1)Carefully clean all surfaces of the engine

block and cylinder head.

2)Also clean the bolt holes thoroughly and

make sure no oil or water is present.

Note! The

result may be that although the bolts are tightened, the cylinder head is not

actually tightened to correct specifications or full pressure is applied to the

cylinder block.

3)Check the flatness in the length and width

of the surface.

4)Make sure deformations, scratches, grooves

or protrusions are removed.

Note! Have

this carried out by a specialist! Depending on the type of head gasket, the

cylinder head should be smoothed extra smooth or slightly rougher.

5)Check and follow the dimensions and

thicknesses as prescribed by the manufacturer.

Note! For

diesel engines, measure the piston overhang to choose the correct thickness of

cylinder head gasket.

6)Carefully place the gasket on the engine

block.

Note! Do not

use liquid sealant.

7)Fit the cylinder head without damaging the

gasket.

8)Use a set of new (torque to yield) bolts.

9)Lubricate the threads and head of the bolt

with a small amount of oil on a cloth.

10)If a washer is prescribed, lubricate it lightly

between the washer and head.

11)Always follow the manufacturer's specific

instructions for head bolt installation.

12)Use only the recommended anti-freeze and corrosion inhibitors.

Replacement Head Gaskets

If you are looking for a replacement head gasket then maybe our head gasket is an ideal choice, offering the following benefits:

· OE quality

· Largest range in global Aftermarket

· Every gasket or seal is individually packed

· Technical data sheet included headsets and head gaskets

· Associated parts detailed on product labels

· Universal kits compared to competitor coverage

· Multiple gasket thicknesses for diesel engines

· Complementary products are also available: head sets, rocker covers, valve stem, and shaft oilseals, inlet/exhaust manifold gaskets

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.