Home Products Rubber Part General Rubber Fittings Rubber Expansion Joint

Rubber expansion joints are also called Rubber Flexible Joint, pipe shock absorbers, Flexible connection, Rubber shock resistant larynx, etc.

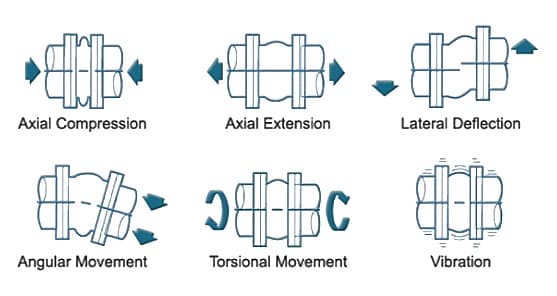

Rubber expansion joints are also called Rubber Flexible Joint, pipe shock absorbers, Flexible connection, Rubber shock resistant larynx, etc.Rubber Expansion Joints are the perfect solution for pipe systems to absorb movements, vibrations or noise, resulting in the significantly prolonged service life of the pipe work and connected equipment.

Classification

According to the structure, rubber expansion joints can be classified into five types: single arch, dual arch, Multiple Arch , spool type, wide arch, and threaded union;

According to their own function properties, they can be classified into: oil-resistant rubber expansion joints, high temperature resistant rubber expansion joints, acid and alkali resistant rubber expansion joints, wear-resistant rubber expansion joints, seawater resistant rubber expansion joints, corrosion-resistant rubber expansion joints, internal oil resistance, external high temperature resistance Rubber expansion joints, negative pressure resistant rubber expansion joints;

According to the shape can be classified into concentric same diameter, concentric different diameter, eccentric different diameter;

According to the working pressure can be classified into: 0.25MPa, 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa, 6.4MPa six grades;

The customer first needs to determine the structure of the selected rubber expansion joint, whether it is a single sphere, double sphere, or a different-diameter joint. and then, determine the type of medium passing through it, temperature, pressure, and other working conditions. At the same time, it is also necessary to provide the standard of the flange, the pressure grade, material.

Application

· Air conditioning

· Paper and pulp

· Cement production

· Power generation

· Chemical production

· Pumps

· Compressors

· Refineries

· Desalination

· Sewage plants

· Fans

· Stormwater

· Glass production

· Transport

· Heating and ventilating

· Water pipes

· Metal production

· Wood processing

· Food and drinks process plants

Production Range

Standard diameter: from Dn 25 to Dn 4000.

Width: from 150 to 400 mm.

Pressure: up to 25 bar.

About Customized Service

About Customized Service

We aim to provide products to work with maximum service life for any operating condition. we are aside from a large standard product program also able to provide customised solutions within Rubber Expansion Joints. As always we welcome challenging tasks, we will deliver the most effective solution from both the operational and economic perspective. This includes size, pressure, temperature, material, standard etc. We will design and customize exclusive molds for you according to specific requirements, and carry out mass production.

Installation Guide

Operating conditions:

Make sure that the rubber expansion joint temperature, pressure, vacuum, displacement ratings and rubber material selection match the system requirements. If system requirements exceed the ratings of the selected rubber expansion joint, please contact the manufacturer immediately. Make sure the choice of rubber material is chemically compatible with the medium and gas that it circulates inside.

· alignment:

In general, rubber expansion joints are not designed to compensate for misalignment errors in piping systems. The misalignment error of the pipe shall not exceed 3mm in any direction. The misplaced installation of the rubber expansion joint will reduce the rated displacement, resulting in huge stress on the rubber material, which in turn will lead to a reduction in the service life. Conduit fittings are installed to ensure alignment of pipes and prevent improper misalignment.

· Anchored:

In any piping system, the position where the direction changes needs to be firmly anchored, and the rubber expansion joint should be installed as close as possible to the anchor point. If no anchoring system is used, it is recommended to install control rods on rubber expansion joints to prevent excessive displacement due to pipeline pressure thrust.

· Pipe rack:

The piping system must be supported so that the rubber expansion joint does not carry any weight from the piping itself.

· Butt flange:

1. Install the rubber expansion joint against the butt flange of the pipe, and then install the bolts so that the bolt head faces the flange of the rubber expansion joint. Rubber expansion joint flange to flange. The length dimension must match the previous length dimension of the two pipes;

2. During the installation process, the rubber expansion joint should be compressed by 3mm-5mm in order to obtain the correct installation size;

3. Ensure the cleanliness of the mating flange. The type of flange is a flat flange or a raised flange exceeding 2mm. During installation, if the rubber part of the rubber expansion. Flange contact, at this time, it is necessary to use an annular gasket to avoid scratching the rubber part on the metal flange surface;

4. Do not install the rubber expansion joint next to the wafer check valve or butterfly valve. Due to the lack of flange mating surface or bolt connection, the rubber ball may be damaged.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.