Home Products Rubber Part General Rubber Fittings Rubber Synchronous Belt

Description

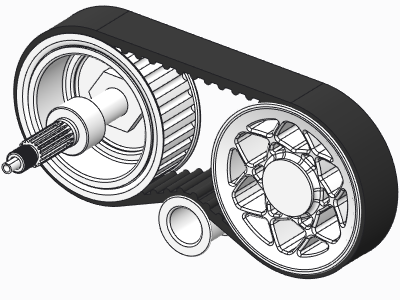

The rubber synchronous belt drive is composed of an endless belt

with equidistant teeth on the inner peripheral surface and a pulley with

corresponding teeth. During operation, the belt teeth mesh with the tooth

grooves of the pulley to transmit motion and power. It is a comprehensive new

type of belt drive with the advantages of belt drive and chain drive gear

drive. Synchronous belt transmission has accurate transmission ratio, no slip,

constant speed ratio, precise transmission, stable transmission, shock

absorption, low noise, wide range of transmission speed ratio, generally up to

1:10, allowable linear speed Up to 50m/s, high transmission efficiency,

generally up to 98%-99%. Transfer power from a few watts to hundreds of

kilowatts. The compact structure is also suitable for multi-axis transmission,

the tension is small, no lubrication is required, and there is no pollution, so

it can work normally in occasions where pollution is not allowed and the

working environment is relatively harsh.

The rubber synchronous belt drive is composed of an endless belt

with equidistant teeth on the inner peripheral surface and a pulley with

corresponding teeth. During operation, the belt teeth mesh with the tooth

grooves of the pulley to transmit motion and power. It is a comprehensive new

type of belt drive with the advantages of belt drive and chain drive gear

drive. Synchronous belt transmission has accurate transmission ratio, no slip,

constant speed ratio, precise transmission, stable transmission, shock

absorption, low noise, wide range of transmission speed ratio, generally up to

1:10, allowable linear speed Up to 50m/s, high transmission efficiency,

generally up to 98%-99%. Transfer power from a few watts to hundreds of

kilowatts. The compact structure is also suitable for multi-axis transmission,

the tension is small, no lubrication is required, and there is no pollution, so

it can work normally in occasions where pollution is not allowed and the

working environment is relatively harsh.

Advantage

· Self-running clean and pollution-free

It operates without polluting the environment, which is critical for

environmentally sensitive equipment.

· Cost-effective

The use of timing belts can significantly reduce downtime and thus increase

production capacity.

· High energy efficiency

The transmission efficiency of the synchronous belt is as high as 99%.

Therefore, system operating costs can be reduced.

· Less maintenance work

Timing belts are ideal for applications where maintenance is inconvenient as it

requires no lubricant or retensioning during use.

· Low noise

The system uses timing belts to minimize noise and vibration.

· Low tension requirement

Timing belts do not require high tension during operation, therefore, the load

on the bearings can be reduced, thereby extending the life cycle of the

bearings and the motor.

· Non-slip, forced drive

Thanks to tight manufacturing tolerances and matching compatibility of timing

belts and pulleys, timing belt teeth and pulley grooves can be perfectly

meshed. As a result, you can produce at a continuous and stable rate, free from

adverse conditions such as rate fluctuations, vibration or jitter.

· Various general tooth profiles

Synchronous belts have many different tooth shapes: STD low noise tooth shape,

high torque tooth shape, traditional trapezoidal tooth shape and HT circular

arc tooth shape, etc.

· Save space and weight

Short center distances and small diameter pulleys make timing belts more

compatible and deliver the same power at a much lower weight than alternatives.

· Wide range of load and speed ratio

The wide variety of timing belt designs allows great flexibility and can be

used in many extended applications. For example: the load-carrying range of the

synchronous belt can range from very small to hundreds of horsepower, and the

speed can change from 1 speed per minute to more than 10,000 revolutions per

minute.

General Specifications

1. Trapezoidal teeth: MXL, XL, L, H, XH, XXH

2. double-sided trapezoidal teeth: DXL, DL, DH

3. semi-circular arc teeth: HTS (HTD)

a) 3M, 5M, 8M, 14M, 20M

b) Double-sided teeth: D3M, D5M, D8M, D14M

4. wedge teeth: STS

a) S2M, S3M, S4.5M, S5M, S8M, S14M

b) Double-sided teeth: DS4.5M, DS8M, DS14M

5. tooth peak concave type: RPP (low noise type, replaceable type HTD)

a) P3M, P5M, P8M, P14M

b) Double-sided teeth: DP5M, DP8M, DP14M

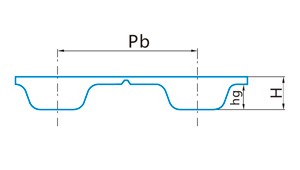

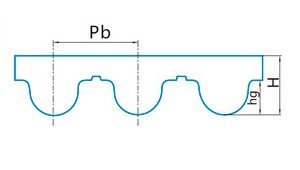

Trapezoidal Synchronous Belt

Type

Pitch(Pb)

Tooth Height(hg)

Belt Thickness(H)

Number of Teeth

Pitch Length

MXL

2.032

0.51

1.14

43-2044

87.38-4153.41

XXL

3.175

0.76

1.52

46-124

146.05-393.7

XL

5.08

1.27

2.3

22-510

111.76-2590.8

L

9.525

1.91

3.6

23-530

219.08-5048.25

H

12.7

2.29

4.3

29-440

368.3-5588

XH

22.225

6.35

11.2

53-220

1177.93-4889.5

XXH

31.75

9.53

15.7

56-144

1778-4572

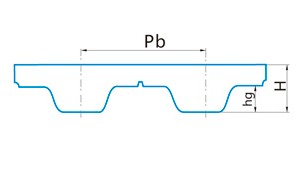

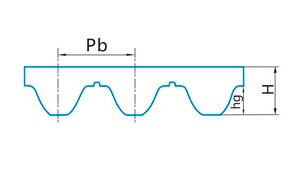

T-toothed Synchronous Belt

Type

Pitch(Pb)

Tooth Height(hg)

Belt Thickness(H)

Number of Teeth

Pitch Length

T2.5

2.5

0.7

1.3

42-312

105-780

T5

5

1.2

2.2

30-400

150-2000

T10

10

2.5

4.5

34-536

340-5360

T20

20

5

8

61-181

1220-3620

Type

Pitch(Pb)

Tooth Height(hg)

Belt Thickness(H)

Number of Teeth

Pitch Length

AT3

3

1.1

1.9

50-238

150-1011

AT5

5

1.2

2.7

40-300

225-3800

AT10

10

2.5

4.5

50-194

370-1940

AT20

20

5

8

18-114

1000-1960

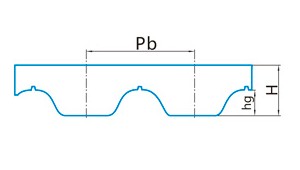

Arc Synchronous Belt

Type

Pitch(Pb)

Tooth Height(hg)

Belt Thickness(H)

Number of Teeth

Pitch Length

3M

3

1.17

2.4

35-1000

105-3000

5M

5

2.1

3.7

35-852

175-4260

8M

8

3.38

5.6

36-565

288-4520

14M

14

6.01

10

56-340

784-4760

20M

20

8.4

13.2

100-260

2000-5200

S-toothed Synchronous Belt

Type

Pitch(Pb)

Tooth Height(hg)

Belt Thickness(H)

Number of Teeth

Pitch Length

S2M

2

0.76

1.36

44-1914

88-3828

S3M

3

1.14

1.9

41-500

123-1500

S4.5M

4.5

1.71

2.81

40-201

180-904.5

S5M

5

1.85

3.35

30-560

150-2800

S8M

8

3.05

5.3

53-500

424-4000

S14M

14

5.3

10.2

69-322

966-4508

Application

1. Polyurethane timing belt T5, T10

T5: Mainly used for data recorders, fax machines, sewing machines

T10: Mainly used in automatic packaging machines, card readers, textile

machines, paper machines, NC lathes, handling machinery

2. Trapezoidal synchronous belts MXL, XL, L, H, XH, XXH are mainly used in the

following industries:

H-Series: Small Mills, Lawn Mowers, Generators, Compressors, Chipping Shears,

Drilling Finishers, Drilling Machines, Glass Bottle Making Machines, Food

Machines, Rope Winders, Rollers, Woodworking Machines

XH series: wood making machine, cutting machine, cutter, mixer, pump, welding

machine, centrifuge, drilling machine, vibration grinding machine, lathe, loom,

paper machine, textile machine

XXH series: air blower, high pressure pump, speed changer, rod mill,

compressor, NC lathe, vibrator, mixer, grinding and drilling machine

MXL / XL series: household sewing machines, typewriters, automatic deposit

machines, currency exchange machines, printing machines, fax machines,

measuring equipment, automatic ticket vending machines, video cameras, paper

feeding devices, printers, CPU supporting equipment, card readers, fish

detection Machines, medical measuring machines, blood pumps, radio equipment,

audio, video recorders, editing machines

L series: vending machines, wipers, packaging machines, elevators, ice

crushers, industrial dryers, unmanned golf carts, computers, copiers, plastic

mirror grinders, food machinery, seaweed harvesting machines

3. Arc tooth synchronous belts S1.5M, S2M, S3M, S5M, S8M, S14M, HTD-8M, HTD-14M

are mainly used in the following industries:

(1) OA machines - copiers, fax machines, computer terminals, printers, X-Y

plotters, word processors

(2) Vending machines - ticket vending machines, ticket inspection machines,

exchange machines, automatic teller machines (ATM), banknote computers

(3) Household appliances - Juicer, Blender, Sewing Machine, Vacuum Cleaner,

Power Tools

(4) electronic applications - computers, video recorders, fish detectors, flaw

detectors, depth sounders, robots

(5) Electronic instruments - rotary machines, recorders, oscilloscopes, data

processing systems, various testing machines

(6) woodworking machinery

(7) textile machinery - spinning machine, twisting machine

(8) paper making machinery - agitator, dryer, calender

(9) Machine tools - drilling machines, lathes, thread cutting machines,

drilling machines, grinding machines, milling machines, NC lathes

(10) others - fans, printing presses, toys, medical equipment, fitness

equipment, printing presses

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.