Home Products Rubber Part General Rubber Fittings Rubber Suction Cup

Description

Rubber Suction Cup is also called Rubber sucker because it sticks to a surface by suction. It works due to air pressure. When we press the rubber sucker on a flat, smooth, surface, its concave rubber cup gets flattened to a large extent, pushing out most of the air from beneath it. When a rubber sucker is pressed on a surface, the air inside the sucker is pushed out thus reducing the air pressure inside the sucker. As the air pressure outside the sucker is more it pushes the sucker and keeps it stuck to its place. Generally, A rubber sucker looks like a small, concave–shaped rubber cup. We have extensive experience in industrial distribution service with standard and custom rubber suction cups. Depending on the final use, We offer rubber suction cups in a variety of sizes and materials for different applications.

Rubber Suction Cup is also called Rubber sucker because it sticks to a surface by suction. It works due to air pressure. When we press the rubber sucker on a flat, smooth, surface, its concave rubber cup gets flattened to a large extent, pushing out most of the air from beneath it. When a rubber sucker is pressed on a surface, the air inside the sucker is pushed out thus reducing the air pressure inside the sucker. As the air pressure outside the sucker is more it pushes the sucker and keeps it stuck to its place. Generally, A rubber sucker looks like a small, concave–shaped rubber cup. We have extensive experience in industrial distribution service with standard and custom rubber suction cups. Depending on the final use, We offer rubber suction cups in a variety of sizes and materials for different applications.

Classification and Application

The main factors that determine the adsorption performance of the suction cup are structure, material, and fit; therefore, from the structure, the suction cup can be classified into round, oval, square, single layer, double layer, multilayer, etc., from the material can be classified into Suction cups are divided into NR, NBR, SI, FKM, PUR, NE, EPDM, SE, etc. From the application, the suction cups can be classified into industrial suction cups, medical suction cups, ordinary suction cups, vacuum suction cups. Special suction cups for the woodworking industry, special suction cups for the packaging industry, special suction cups for the glass industry, special suction cups for high-temperature workpieces, special suction cups for plastic film and paper, etc.

Because rubber suction cups have many advantages, rubber suction cups are widely used. At present, it is used as a fixed tool accessory in kitchen, food, electronic accessories, mechanical hardware, power chemical industry, automobile, industrial robot, construction, packaging and other industries.

Choose The Best Solution

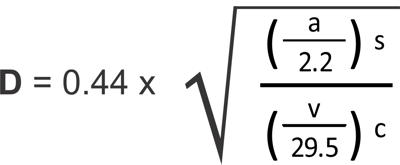

Vacuum suction cups can hold, lift or turn virtually any kind of material in the production process. The contact between a suction cup and the object to be handled is soft and light, and the technique is simple and safe. It is very important to choose the most appropriate type of vacuum suction cup, to obtain optimal results. with our range of products, you can find the best solution for every task. The selection of a suction cup depends on particular conditions such as surface quality and structural stability of the work piece to be lifted and the desired material, shape, etc. of the suction cup. However, a simplified formula can be used to generate a theoretical estimate based on a few known values. The diameter of the suction cup can be determined using the following formula:

1)

US Units:

D = Diameter in inches

a = Mass in lbs.

c = Number of cups

v = vacuum in inches of Hg

s = safety factor (at least 2)

2)

Metric Units:

D = Diameter in mm

m = Mass in kg.

c = Number of cups

b = vacuum in bar

s = safety factor (at least 2)

A safety factor of at least 2 for horizontal lifts should always be used to compensate for numerous variables surrounding lifting applications while a safety factor of at least 4 should be used for vertical or tilting applications. A pull-off test should be performed at our factory to determine the absolute suction cup for your particular application. Contact one of our application engineers for more information.

When shouldn't we use vacuum suction cups?

While vacuum suction cups can be useful in many applications, there are certain situations where they may not be the best choice. Here are some examples:

1. Rough or porous workpieces: Vacuum suction cups work best on smooth, non-porous surfaces such as glass industry or polished metal. Rough or porous surfaces, such as wood or concrete, may not provide a strong enough seal for the suction cup holder.

2. High-temperature environments: Suction vacuum cups can become less effective at high temperatures, as the heat can cause the seal to break down or the cup to deform. In such cases, other types of fasteners or clamps may be more appropriate.

3. Extremely heavy loads: While vacuum suction cups can be used to lift and move heavy objects, such as wood handling, there are limits to their weight capacity. It's important to carefully evaluate the load and select a suction cup with an appropriate weight capacity to avoid accidents or damage.

4. Hazardous materials: Vacuum suction cups should not be used to handle hazardous materials or substances that could contaminate the cup or the vacuum system.

5. Moving objects: Vacuum suction cups are designed for use on stationary objects. They may not be suitable for applications where the object is moving or subject to significant vibration, as this can cause the suction cup to lose its seal.

Overall, it's important to carefully consider the specific application and requirements before selecting a vacuum suction cup. It's recommended to use suctions cups

Rubber Suction Cups Main Materials

Material

Hardness

Working Temperature

Abrasion

Aging Weathering

Oil & Grease

Electric

Nitrile Rubber(NBR)

30-90

-20℃-105℃

Good

Poor

Perfect

Poor

Silicone Rubber(VMQ)

10-90

-40℃-230℃

Poor

Perfect

Good

Perfect

Polyurethane(PU)

30-90

-30℃-100℃

Perfect

Perfect

Poor

Good

Neoprene Rubber(CR)

30-80

-40℃-120℃

Good

Good

Good

Good

Natural Rubber(NR)

40-80

-50℃-90℃

Perfect

Average

Average

Good

Fluororubber(FKM&FPM)

50-90

-50℃-300℃

Perfect

Perfect

Perfect

Average

Sponge Rubber

28-33

-10℃-80℃

Average

Average

Average

Average

Suction cups come in a wide range of materials to meet specific application requirements. Common materials include nitrile, silicone, and natural rubbers, fluoroelastomers, and polyurethanes. Some materials, for example, are particularly suited for smooth, rough, or oily surfaces, or easily damaged workpieces.

Customer Service

(Shore A)

(℃)

Resistance

Ozone

Resistance

Insulation

Professional Sales Teams and Quick Reply: Our sales engineers will well work together with mold designing department, production department and QC department, etc, in aim to producing better qualified products & parts for customers

Free Design Analysis Support for Moldability and Manufacturability: we have two rich experience design engineers will cover your projects from ideas & drawings to end use.

Customer's Design Patent Protection: Only accept custom-made projects according to customers' design drawings or samples. Our company will not sell customers' products & parts to other customers & persons, as customers had paid mold-making cost to us and molding belong to their properties. We can sign NDA with customers.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.