Home Products Rubber Part Rubber Seal Ring Rubber X-Ring Seal

Description

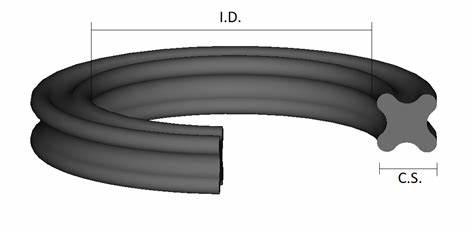

X-

Ring Seal(Quad Ring) is a circular rubber sealing ring with four sealing lips, which can

act as a two-way seal. X-Ring has the advantages of convenience, economy, and

wide application fields. Compared with the O-Ring, it improves the problems of

twisting, extrusion, and low performance. It can better reflect its advantages

when used in the sealing system of reciprocating motion, rotary motion, and

spiral motion. It has good interchangeability with the groove of AS568A

standard series O-Ring. The X-Ring Seal can be used in sealing gas and liquid

in dynamic or static occasions, suitable for reciprocating pistons, piston

rods, and plungers, and also suitable for shafts and mandrels under swinging,

spiral, and rotating conditions.

X-

Ring Seal(Quad Ring) is a circular rubber sealing ring with four sealing lips, which can

act as a two-way seal. X-Ring has the advantages of convenience, economy, and

wide application fields. Compared with the O-Ring, it improves the problems of

twisting, extrusion, and low performance. It can better reflect its advantages

when used in the sealing system of reciprocating motion, rotary motion, and

spiral motion. It has good interchangeability with the groove of AS568A

standard series O-Ring. The X-Ring Seal can be used in sealing gas and liquid

in dynamic or static occasions, suitable for reciprocating pistons, piston

rods, and plungers, and also suitable for shafts and mandrels under swinging,

spiral, and rotating conditions.

The

X-Ring is a kind of groove that can be installed in a groove with a small

compression rate to reduce friction and can also be used in the groove of an

O-ring of the same specification. The X-shaped sealing ring has low friction,

can better overcome torsion, and can obtain high lubrication; it can be used as

a moving sealing element at a lower speed and is also suitable for static

sealing.

Advantage

1) During reciprocating motion, it is not easy to produce spiral twist damage;

2) Due to the small radial precompression formed, the contact pressure is small and the friction force is also small, which is not easy to cause gap bites and reduces the power loss of moving parts;

3) Due to the uniform contact pressure, the leakage is small;

4) Since the parting surface of the mold is set between the two lips, the flash will not affect the sealing effect.

5) The X-shaped sealing ring will form a lubricating cavity between the sealing lips, which has small friction resistance and starting resistance.

6) Since its flash edge is located in the recess of the section, the sealing effect is good.

7) Non-circular cross-section can avoid rolling during reciprocating motion. Therefore, the X-Ring has the characteristics of long life and good sealing effect in dynamic sealing occasions

Technical Data:

|

Item |

Dynamic Seal |

Static Seal |

|

|||

|

Reciprocating |

Rotary |

|

||||

|

Pressure |

With Retaining Ring |

30 |

15 |

40 |

|

|

|

No Retaining Ring |

5 |

/ |

5 |

|

||

|

Speed(m/s) |

0.5 |

2 |

/ |

|

||

|

Temperature(℃) |

Low: -30℃-110℃ |

|

||||

How to choose an X-Ring seal?

1. The application range of the X-Ring is very wide, and the appropriate material should be selected according to the temperature, pressure, and medium. Choose according to different environments. Commonly used materials are NBR, FKM, SIL, FLS, HNBR, ACM, FFKM, IIR, VMQ, EPDM, CR, BU, PTFE, NR, etc.

2. In order to adapt the X-Ring as a sealing element to a given application, the mutual constraints between all operating parameters should be considered. The application must also consider peak temperature, continuous operating temperature, and operating cycle. In rotating applications, the temperature rise due to frictional heat must also be considered.

3. If the diameter of the shaft hole is known, select the appropriate size according to the following criteria:

1). Static seal or reciprocating linear motion:

Hole seal: The inner diameter of the X-Ring should be adapted to the groove, or about 2% smaller than the outer diameter of the groove because the pre-compression force generated by pre-compression can effectively prevent the star-shaped sealing ring from twisting.

Shaft seal: The inner diameter of the X-Ring should be equal to or appropriately larger than the outer diameter of the shaft by about 0.2 mm-0.3mm, and it can also be 1% larger than the outer diameter of the shaft. As a result, the sealing ring can be installed more easily and at the same time achieve a longer service life.

2). Rotary motion seal:

Rotary seal: The inner diameter of the X-Ring should be about 2%-5% larger than the diameter of the shaft it seals. Because the sealing ring will generate friction and heat when it is used in a rotating motion, and the elastomer will shrink after being heated (Joule effect). In order to make the sealing ring lubricated and work reliably, it is necessary to choose an X-Ring whose inner diameter is larger than the shaft diameter.

Generally, a sealing ring with a smaller cross-section can meet the needs of static sealing, on the contrary, a sealing ring with a larger cross-section should be selected to meet the requirements of dynamic sealing. In the case of high pressure or a large extrusion gap, it is necessary to use a rubber material with a higher hardness. The best way is to add a PTFE backing ring. To prevent high-pressure extrusion damage.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.