Home Products Rubber Part General Rubber Fittings Rubber Bellows

Description

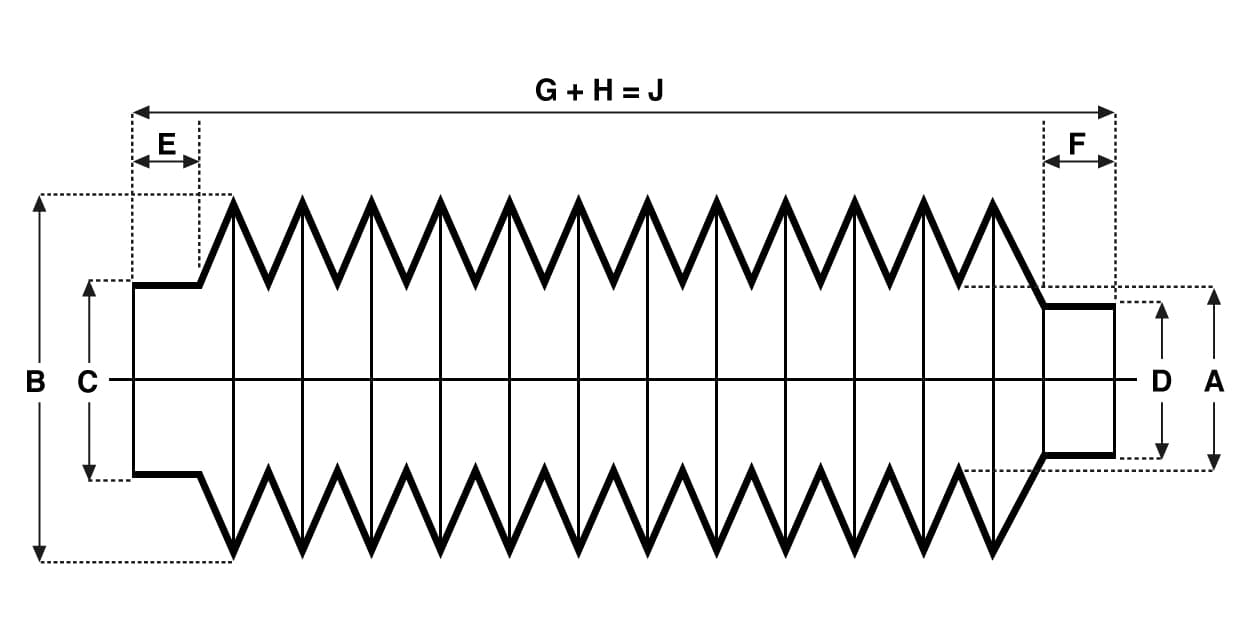

Rubber bellows are also called rubber corrugated sleeves, rubber dust covers, and rubber corrugated dust jackets. Rubber bellows mainly use the expansion and contraction of corrugations to achieve the unique properties of rubber, such as high elasticity, high air tightness, medium resistance, weather resistance and radiation resistance. The rubber bellows is preformed with pure rubber material and then vulcanized by high temperature molding, or made of polyester cord with high strength and strong cold and heat stability, and then cross-linked by high pressure and high temperature molding. The internal density is high, can withstand high pressure, and has excellent elastic deformation effect. Different from metal bellows, the biggest feature of rubber bellows is shock absorption and noise reduction. The design of rubber bellows varies widely according to the working conditions and performance requirements. Common parameters include size, material, hardness, color, temperature, pressure, working environment, etc. Rubber bellows have good compressibility and resilience, small permanent deformation, no softening at high temperature, no decomposition, no hardening at low temperature, no brittle cracking, good corrosion resistance, small friction coefficient, good wear resistance, good aging resistance , durable features. Rubber bellows are widely used in aviation, petroleum, chemical industry, metallurgy, electric power, papermaking, medicine, food, wood, tobacco, etc. , transportation and other industries. Rubber bellows are more widely used in the machinery and auto parts industry because they can be stretched without affecting the performance of the product, and they have the advantage of no noise.

Rubber bellows are also called rubber corrugated sleeves, rubber dust covers, and rubber corrugated dust jackets. Rubber bellows mainly use the expansion and contraction of corrugations to achieve the unique properties of rubber, such as high elasticity, high air tightness, medium resistance, weather resistance and radiation resistance. The rubber bellows is preformed with pure rubber material and then vulcanized by high temperature molding, or made of polyester cord with high strength and strong cold and heat stability, and then cross-linked by high pressure and high temperature molding. The internal density is high, can withstand high pressure, and has excellent elastic deformation effect. Different from metal bellows, the biggest feature of rubber bellows is shock absorption and noise reduction. The design of rubber bellows varies widely according to the working conditions and performance requirements. Common parameters include size, material, hardness, color, temperature, pressure, working environment, etc. Rubber bellows have good compressibility and resilience, small permanent deformation, no softening at high temperature, no decomposition, no hardening at low temperature, no brittle cracking, good corrosion resistance, small friction coefficient, good wear resistance, good aging resistance , durable features. Rubber bellows are widely used in aviation, petroleum, chemical industry, metallurgy, electric power, papermaking, medicine, food, wood, tobacco, etc. , transportation and other industries. Rubber bellows are more widely used in the machinery and auto parts industry because they can be stretched without affecting the performance of the product, and they have the advantage of no noise.

Commonly Used Materials for Rubber Bellows

• Natural Rubber (NR)

• Silicone Rubber (VMQ)

• Neoprene®, Chloroprene (CR)

• URETHANE

• Polyisoprene (IR, NR)

• Styrene-Butadiene (SBR)

• Butyl (IIR)

• Ethylene-Propylene (EPDM, EP)

• Nitrile, Buna-N (NBR)

• Fluorosilicone (FVMQ)

• Viton®, Fluorocarbon (FKM)Our engineers are committed to analyzing your specific needs to create custom rubber bellows to your exact specifications. We utilize unique manufacturing techniques and select materials to provide the correct solution for your application. Jefferson Rubber can fill orders both low and high volume as well as providing prototypes.

|

MATERIAL |

ABBREVIATION |

FLEX FATIGUE |

RELATIVE PRICE |

TEMPERATURE RANGE |

OZONE, UV RESISTANCE |

OIL RESISTANCE |

|

Ethylene-Propylene |

EPDM |

Excellent |

Excellent |

-70F to 250F |

Excellent |

Poor |

|

Nitrile |

NBR |

Fair |

Good |

-30F to 250F |

Poor |

Excellent |

|

Neoprene / Chloroprene |

CR |

Excellent |

Excellent |

-60F to 220F |

Good |

Fair |

|

Silicone |

VMQ |

Excellent |

Fair |

-175F to 450F |

Excellent |

Fair |

Applications

• Cooling water systems

• Condensers

• Gas lines

• Water pipelines and piping

• Pumps

• Turbines

• Boilers

• Automotive suspension systems

• Mechanical vibration dampers

Features and Benefits

• Alleviation of stress on pipelines and piping resulting from product pressure, thermal expansion, misaligned piping.

• Reduced noise

• Flexible and secure seal around moving parts and components

• Extended life of system components

Customized Service

We are a complete resource for all your custom rubber molding requirements. We have state-of-the-art custom injection molding processes, combined with the latest equipment, experienced engineer and a highly trained staff ensures that your custom molded rubber parts meet your precise requirements. When you work with us you can depend on quality custom rubber molding production from the design assistance to manufacturing to final assembly. Custom rubber is our specialty, and we have the capability to provide prototyping, production, finishing, and assembly, so you don’t have to work with multiple companies. we are your one stop resource for all your custom rubber molding requirements. At the same time, quality and customer satisfaction is our focus and we work continuously to lower costs and increase efficiency which is passed onto our customers. Contact us for all of your custom rubber injected molded parts. If the order needs to provide size, material, hardness, color, temperature, pressure, working environment, etc. if there are special requirements, drawings should be provided.

Name: Alex Zhang

Mobile:+86 13171716031

Whatsapp:8613171716031

Email:alex@ovictors.com

Name: Tex

Whatsapp:8618310003967

Email:tex@ovictors.com

Name: Lisa

Whatsapp:8618330856285

Email:info@ovictors.com

Add:Tengda East 7#,Qianjin Street,Hengshui,053000,Hebei,China.